CNC cylindrical grinders G1 Series (Type Racing,Sports,Basic)

G1 Series

Fastest for everything

It causes a revolution in production based on the highly-productive and highly-reliable technology that we have cultivated in production of automobile engines.

Product VDO Inquiries about products

Features . Outline

|

Industry leadingQuality

Dimensions variation:?1/3

compared to conventional grinder |

Unrivaled ProductivityAchieve both overwhelming high power

and extremely high speed operation |

|

|

Dedicated OperabilityQuality

Equipped with a grinding cycle with high

frequency of use as a standard |

Evolved TAKTICAReal-time feedback of measurement

values to the facility to provide stable,

good-quality machining |

|

|

Carbon neutralityQuality

Reduced electric power for non-machining

time & during machining time |

Machine Specifications

| Distance between centers | mm | 200/350/500 | |

| Swing over table | mm | φ320 | |

| Height from tde floor to center of tde machine | mm | 1000 | |

| Max. grinding diameter | mm | 0~φ150 | |

| Load between centers | kg | 20 | |

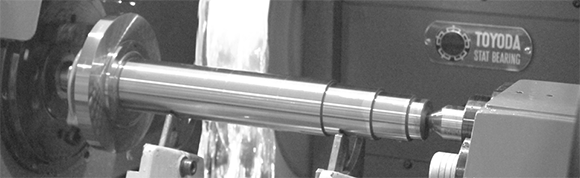

| Wheel spindle |

Roller bearings

[STAT BEARING (fluid)]

|

||

| Wheelhead | Rapid feedrate | m/min | φ40 |

| min. input increment | mm | φ0.0001 | |

| Wheelhead traverse | Rapid feedrate | m/min | 30 |

| min. input increment | mm | 0.0001 | |

| Operation panel |

FANUC 10.4 inch

[TOYOPUC-TOUCH 15 inch]

|

||

| Control unit |

FANUC 0i-TF Plus

[TOYOPUC-GC70]

|

||

| Electrical equipment | Power supply voltage AC200V、Control voltage DC24V |